FORWARD FOODING

THE BLOG

Cold Plasma Technology: The Future of Food Safety

In the ever-evolving landscape of food technology, innovations continue to emerge to address challenges related to food safety, preservation, and sustainability. A recent technical intervention for maintaining food quality and safety that is gaining traction is cold plasma. With its unique ability to combat harmful pathogens while extending the shelf life of food products, cold plasma is revolutionising the way we approach food processing and preservation.

Plasma was discovered in 1928 and in recent years, cold plasma has piqued the interest of researchers across various domains and its application in decontamination and food safety has garnered significant attention. With support from entities like the USDA and consumer advocacy groups, ongoing research into cold plasma technology holds immense promise for the future.

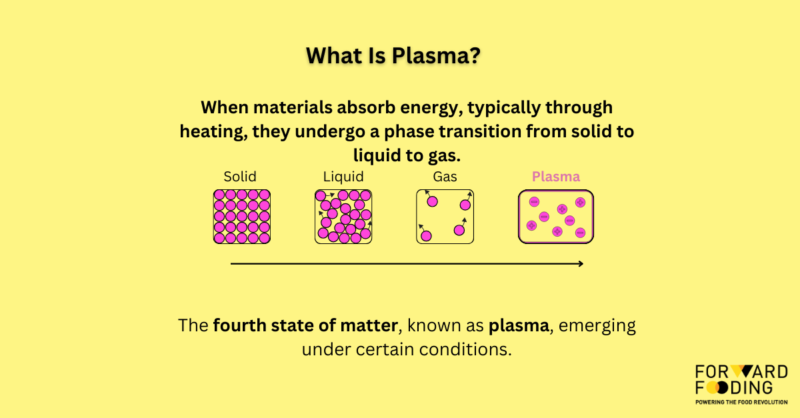

As the fourth state of matter, plasma emerges by dissociating gas molecules into a blend of charged particles. Cold plasma, specifically, is generated by propelling fast-moving electrons through cool gases. This unique combination of energy and low temperature offers novel capabilities and opens up a realm of possibilities in food safety and beyond.

Cold Plasma and Shelf Life

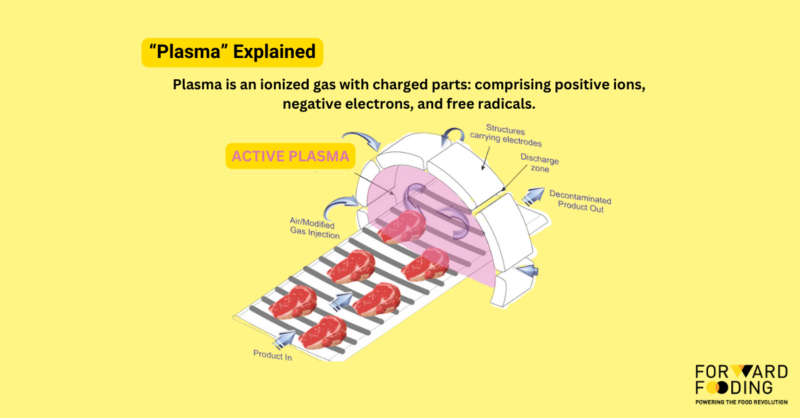

At its core, cold plasma involves the creation of ionised gas at or near room temperature. This plasma consists of charged particles, including ions, electrons, and free radicals. What sets cold plasma apart is its non-thermal nature, making it a safer and more efficient alternative to traditional heat-based methods of food processing. By harnessing the power of electricity, cold plasma can effectively decontaminate food surfaces without compromising taste, texture, or nutritional quality.

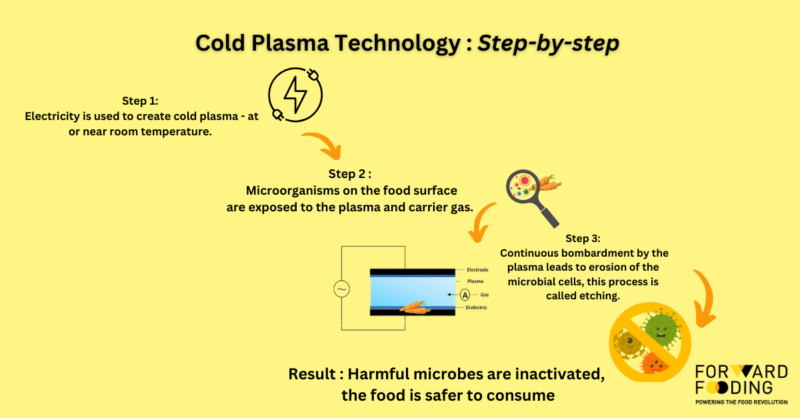

Step-by-Step Guide to Cold Plasma Technology

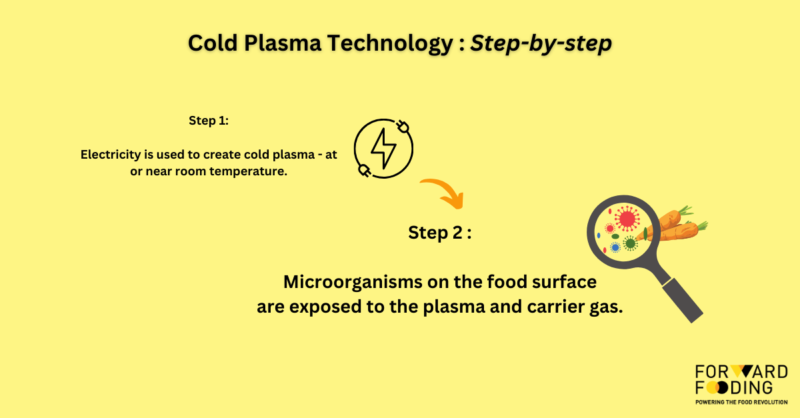

1. Generation of Cold Plasma:

Cold plasma is generated by applying an electric field to a gas, typically air, oxygen, nitrogen, or helium. This process ionises the gas molecules, creating a mixture of charged particles.

2. Interaction with Microorganisms:

Once generated, the cold plasma is directed towards the food surface, where it interacts with any present microorganisms, including bacteria, viruses, and fungi.

3. Inactivation of Pathogens:

The reactive components of cold plasma, such as atomic and molecular radicals, initiate a series of chemical reactions within the microbial cells. This leads to the disruption of cell membranes, denaturation of proteins, and ultimately, the inactivation of pathogens.

4. Preservation of Food Quality:

Unlike traditional sterilisation methods that rely on high temperatures, cold plasma preserves the quality and integrity of food products. It does not cause thermal damage or alter the sensory attributes of the food, ensuring that it remains safe and palatable for consumption.

5.Extension of Shelf Life:

By effectively reducing microbial contamination, cold plasma helps extend the shelf life of perishable foods. This not only reduces food waste but also enhances food safety throughout the supply chain, from production to consumption.

Embracing Cold Plasma: A Glimpse into the Future of Shelf Life

As we envision the future of food preservation, cold plasma emerges as a with its unparalleled ability to effectively combat pathogens while preserving the quality and integrity of food products, cold plasma technology represents a transformative force in the food industry. From extending shelf life and reducing food waste to enhancing food safety throughout the supply chain, the potential advantages are vast. However, like any emerging technology, cold plasma also presents challenges and considerations. From regulatory hurdles to cost-effectiveness and scalability, there are factors to weigh in its widespread adoption.

As researchers continue to unravel its full potential and industries embrace its capabilities, we embark on a journey towards a future where food stays fresher, safer, and more sustainable for longer durations.

In conclusion, cold plasma technology could represent a game-changer in the world of food technology in the future. Its ability to combat pathogens while preserving the quality and shelf life of food products makes it a valuable tool for food manufacturers, processors, and consumers alike.

As we continue to explore innovative solutions to meet the growing demands of a global food market, cold plasma stands out as a promising technology with the potential to revolutionise food safety and sustainability practices for years to come.

Learn more about our Taxonomy in our Activity Spotlight for Food Safety and Traceability. Explore how other innovative technologies like cold plasma are utilised by companies in transforming the industry.

Follow us

Sponsored Articles

8 February 2024

Future Food-Tech returns to San Francisco on March 21-22 Over 1,700 food-tech leaders, from CPG brands, retailers, ingredient providers, [...]

1 February 2023

The 4th edition of FoodTech 500 is taking off and we are excited to partner with NEOM for the third consecutive year to support the best international AgriFoodTech entrepreneurs.

10 February 2022

One of the elements we enjoy the most here at Forward Fooding about working with AgriFoodTech startups is being [...]

4 January 2022

At Forward Fooding, we believe in the power of innovation and collaboration to power the food tech revolution and transform [...]

27 April 2021

TWO Inc, a Tokyo-headquartered wellness company, has just launched its new “healthy junk food” concept to offer Japanese consumers nutritious [...]