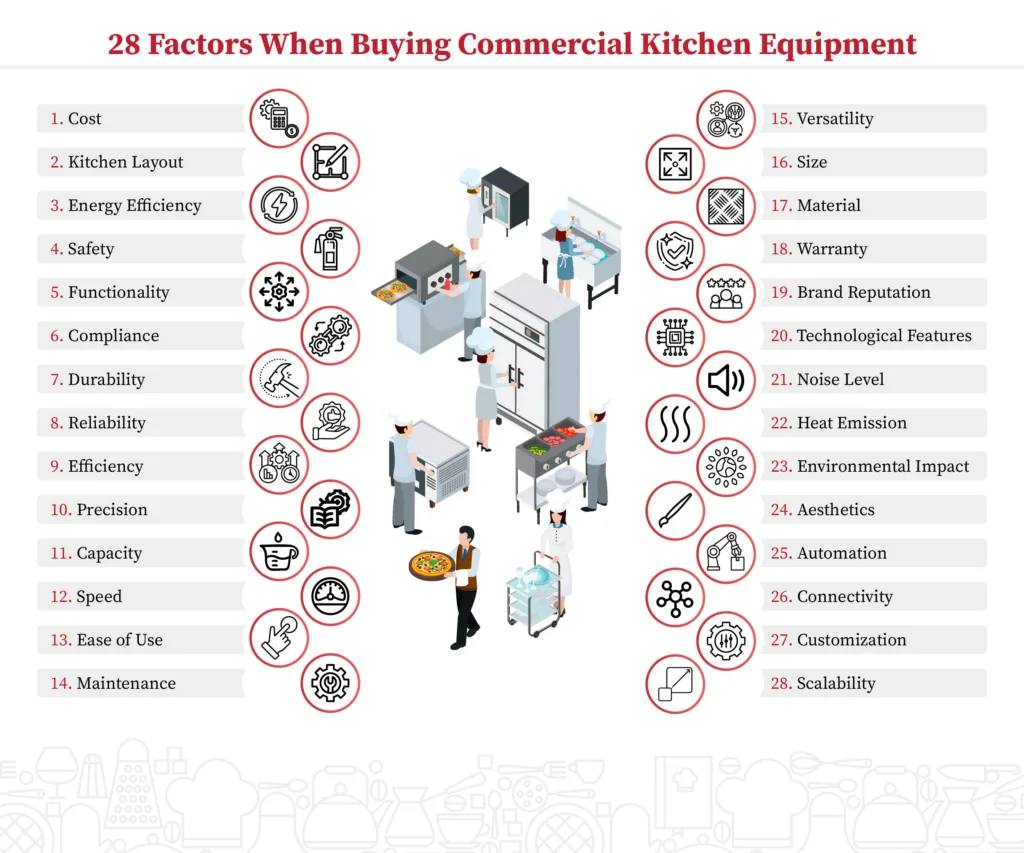

Purchasing commercial kitchen equipment is a significant investment that impacts the efficiency, profitability, and overall success of your foodservice operation. With a vast array of options available, making informed decisions that align with your specific needs and budget is crucial. This comprehensive guide identifies the key factors below that a kitchen manager or foodservice business owner must consider when buying commercial kitchen equipment.

- Cost

- Kitchen Layout

- Energy Efficiency

- Safety

- Functionalities

- Compliance

- Durability

- Reliability

- Efficiency

- Precision

- Capacity

- Speed

- Ease of Use

- Maintenance

- Versatility

- Size

- Material

- Warranty

- Brand Reputation

- Technological Features

- Noise Level

- Heat Emission

- Environmental Impact

- Aesthetics

- Automation

- Connectivity

- Customization

- Scalability

These 28 factors provide a comprehensive framework for making informed decisions when buying commercial kitchen equipment. By carefully evaluating these aspects, you can select the right appliances to optimize your operations, enhance profitability, and deliver exceptional culinary experiences to your customers.

Addressing challenges such as balancing high-tech features with practicality, effective maintenance strategies, closing training and skill gaps, ensuring ergonomic workspaces for staff well-being, assessing cost versus value, and adapting to changing culinary trends is essential in the decision-making process. Collectively, these elements ensure a harmonious and productive kitchen environment.

1. Cost

Cost is often the primary consideration when buying commercial kitchen equipment, as it lays the foundation for budgeting and financial planning. However, a comprehensive cost understanding is more than just adherence to a predetermined budget. Cheaper doesn’t always equate to better. Yes, initial affordability sounds tempting, but a more holistic approach that considers the total ownership cost yields significant savings in the long run.

Energy-efficient equipment or low-maintenance appliances reduce operation expenses. Try to strike a balance between affordability and efficiency. Also, always research extensively for price reductions through negotiations and instant rebate programs.

2. Kitchen Layout

When considering the purchase of commercial kitchen equipment, understanding your kitchen layout is crucial. The layout dictates the spatial arrangement and guides your buying decisions, ensuring the equipment you choose fits seamlessly in size and function.

Whether you opt for larger appliances for a spacious kitchen or prioritize compact, stackable options for a smaller, galley-style setup, the layout significantly influences the type and size of equipment you buy. This ensures an efficient workflow and optimizes available space, impacting both the functionality and aesthetics of your kitchen.

3. Energy Efficiency

Energy efficiency is a multidimensional factor when buying commercial kitchen equipment. Investing in energy-efficient equipment can lead to substantial savings. The U.S. Environmental Protection Agency (EPA) estimates that ENERGY STAR-certified commercial kitchen appliances can save businesses about 340 billion kWh annually, leading to financial savings of more than $30 billion and significantly reducing greenhouse gas emissions. Energy-efficient commercial kitchen equipment can save up to 25% or more on energy costs annually.

- Purchasing energy-efficient appliances impacts overall operational costs by reducing utility bills.

- Such products support the global drive toward sustainability, minimizing your establishment’s ecological footprint.

- Your focus on a greener future demonstrates your corporate social responsibility and hones your brand reputation.

- The more advanced technologies in energy-efficient equipment also enhance performance and productivity.

- Customers, stakeholders, and regulatory bodies value sustainable businesses, so they offer incentives and rebates for investing in energy-efficient appliances.

4. Safety

Failure to consider safety jeopardizes the well-being of your staff and patrons. It also exposes your business to potential fines and legal consequences. According to the National Safety Council (NSC), there were over 98,000 workplace injuries in foodservice establishments in 2023, of which 11% involved cuts, burns, or slips from equipment.

Modern equipment is furnished with advanced safety features to prevent accidents and ensure a secure working and dining environment. For example, flame failure on gas appliances shuts off gas flow in the absence of a flame. Similarly, interlock systems on ovens and fryers ensure these appliances only work when their doors are securely closed. Safety directly influences people’s health, so always let it be your guiding factor when buying commercial kitchen equipment.

5. Functionality

Equipment functionalities are crucial for improving a chef’s culinary prowess. Functional features like programmability, automation, or ease of use streamline operations and improve workflow. Opting for multifunctional equipment is a strategic move that saves you time, money, space, and labor. Multitasking marvels such as combination ovens and tilt skillets integrate multiple capabilities in a single appliance. Yet, do not let the allure of the latest kitchen gadgets mesmerize you. Precisely align equipment functionalities with the specific tasks required in your kitchen to not overpay for unnecessary functions.

6. Compliance

All foodservice facilities must meet local and national legal and health standards. Regulatory bodies like the Food and Drug Administration (FDA), National Sanitation Foundation (NSF), Environmental Protection Agency (EPA), and local health and fire departments regulate the standards required for a safe and hygienic operation. Failure to comply with these codes results in penalties, closures, and reputational damage. Therefore, prioritize compliance when buying commercial kitchen equipment to run your business smoothly and lawfully.

7. Durability

Durability refers to the inherent build quality that enables appliances to withstand rigorous commercial use over an extended period. High-quality materials, such as stainless steel, robust and well-engineered construction with reinforced frames and joints, and enhanced insulation are some indications of durable equipment.

The ROI for high-quality, durable kitchen equipment is significant. According to industry studies, high-grade equipment can last up to 10 years or more, reducing the frequency of replacements and repairs. They promote productivity and efficiency for meeting high-volume demands and give chefs and food prep staff confidence. The investment in premium equipment translates into long-term savings and consistent performance.

8. Reliability

Reliability is essential for consistent kitchen operations. Delays in service, inconsistent cooking results, or unexpected machine malfunctions are unaffordable in demanding commercial settings. Reliable appliances eliminate these risks and help maintain a seamless flow of kitchen operations without any disruptions. This directly translates into increased customer satisfaction. Whether during peak hours or prolonged service periods, reliability becomes a strategic factor when buying commercial kitchen equipment for chefs to focus more on their culinary creations.

9. Efficiency

Efficiency is a pivotal factor when buying commercial kitchen equipment to manage operational costs. Foodservice is a fiercely competitive industry where margins matter. Any feature that minimizes the use of resources, time, and energy maximizes output and makes a difference in your business’s success. The National Restaurant Association suggests that labor costs in a restaurant can constitute up to 30-35% of total revenue.

Efficient kitchen equipment can optimize staff productivity, reducing labor hours needed for food preparation and cleaning, thus contributing to overall cost savings. Another easy way to check efficiency is to look for relevant certifications, such as ENERGY STAR. You can also search specifications that lower water consumption, expedite cooking or food processing times, and facilitate operation and maintenance.

10. Precision

In purchasing commercial kitchen equipment, chefs seek precision to maintain control over the cooking process and meet customer expectations. This requires equipment that offers accuracy in temperature, timing, portioning, and other critical aspects. When buying, look for features like programmable settings, digital controls, uniform heat distribution, and temperature probes. These precision indicators ensure that meals are cooked and served perfectly, aligning with the culinary team’s standards and customer demands. Selecting equipment with these capabilities is essential for achieving consistency and excellence in every dish prepared.

11. Capacity

The equipment capacity is key for meeting production demands. Matching capacity with your kitchen’s needs and expected foot traffic is a significant factor when buying commercial kitchen equipment. Mismatches cause serious issues, and overestimation results in the inefficient use of space and resources. For instance, an ice maker generating more than required ice means extra hassle for handling the excess melts. Underestimation leads to bottlenecks and longer wait times. A balanced capacity evaluation also involves demands during peak periods and growth potential.

12. Speed

Speed is vital to keep up with fast-paced service in the dynamic foodservice. Life is moving very swiftly, and people have less and less time to wait for their meals. Speed is becoming a convincing reason for preference over food outlets, making it a top-rated factor when buying commercial kitchen equipment. Choose rapid-cook ovens that use advanced cooking technologies to reduce cooking times without compromising taste quality. Similarly, dishwashing machines that complete a wash cycle quickly facilitate the rapid turnaround of clean dishes during peak hours.

13. Ease Of Use

When selecting commercial kitchen equipment, prioritizing ease of use is vital for ensuring staff efficiency and managing employee turnover. The purchasing decision should focus on user-friendly attributes such as straightforward controls, clear interfaces, and ergonomic designs. These features make equipment easier for new and seasoned staff to operate and reduce the chances of mistakes and training time. This focus on ease of use during buying process is key to maintaining smooth operations, especially during busy periods, and contributes to improved service quality and customer satisfaction.

14. Maintenance

Maintenance affects the long-term usability and hygiene of commercial kitchen equipment use. Regular maintenance can prevent expensive repairs and prolong the lifespan of kitchen equipment, and it always remains clean for sanitary operation.

The Food Service Technology Center (FSTC) advises that a well-maintained piece of equipment can have a life expectancy of 15-20 years, whereas poorly maintained equipment may need replacement within 5 years, significantly affecting long-term financial planning. Food particles not removed from a food processor impair its performance. Equipment with easily accessible parts and detailed servicing manuals is helpful. Plus, self-cleaning capability removes the need for manual effort. Appliances with self-diagnostic function and those that are engineered to require fewer regular maintenance cycles are also sought-after features.

15. Versatility

When buying commercial kitchen equipment, versatility is a key consideration for culinary flexibility and creativity. Versatile appliances, like convection ovens and multifunctional food processors, allow chefs to experiment with diverse cuisines, adapt to seasonal ingredients, and satisfy varying customer tastes. Choosing such adaptable equipment during purchasing is essential for enhancing menu offerings, keeping up with culinary trends, and staying competitive in the dynamic food industry.

16. Size

Size is a multifaceted factor when buying commercial kitchen equipment. It must be suitable for the kitchen’s physical space. Yet, there are more facets to refine operational efficiency without overcrowding the kitchen and underutilizing your equipment. So, before making any purchases,

- Measure the available space and check the dimensions of the appliance you’re considering to prevent any spacing problems.

- Ensure that it fits comfortably within your kitchen layout.

- Consider the size of doorways and access points to move it in and out of the kitchen easily.

- Align the size with the required throughput: larger equipment for high-volume businesses.

17. Material

Material selection impacts equipment longevity and food safety. Durability, corrosion to resistance, and ease of cleaning are the most critical material-related factors when buying commercial kitchen equipment. Stainless steel has all these features, making it a kitchen staple for cooking and dishwashing appliances. Aluminum is prized for its lightweight nature and excellent heat conductivity. It is suitable for cookware and certain food prep tools. Glass and high-quality plastics are preferable for food storage to prevent flavor transfer. Additionally, materials approved for direct food contact mitigate the risk of contamination.

18. Warranty

Warranties provide assurance and protect your investment. Check the manufacturer’s warranty period, coverage details, exclusions, and other terms and conditions. A comprehensive warranty means peace of mind, safeguarding you against unexpected breakdowns and additional unseen costs. Purchasing an extended warranty or a maintenance package guarantees continuous and reliable performance of your kitchen equipment.

19. Brand Reputation

Investing in the brand reputation factor when buying commercial kitchen equipment provides good value for money and trust in product performance. Reputable brands deliver durable products, efficient solutions, and always supportive & responsive customer service. The level of reliability and longevity transcends the immediate cost considerations. Established brands with a strong name have a proven track record that meets the highest industry standards. Extensively research verified user reviews, industry recognition, and market presence in your navigation of brand alternatives.

20. Technological Features

Technological features in modern commercial kitchen equipment elevate operation efficiency and food quality to unprecedented levels. Advanced technologies like touch-screen interfaces, programmable settings, and cloud connectivity enable precise control over cooking parameters, enhancing efficiency and food quality. Investing in smart ovens with sensor technology, automated vegetable cutters, high-speed blenders, super-automatic espresso machines, and conveyor dishwashers streamlines operations. These technologically advanced tools improve the culinary process and reduce long-term operational costs by increasing productivity and minimizing waste.

21. Noise Level

Noise level is often overlooked but crucial when buying commercial kitchen equipment. Restaurant kitchens are inherently bustling settings with multiple appliances simultaneously in operation. Excessive noise from food processors, blenders, dishwashers, and ventilation systems working together causes workplace stress. Their cacophony impacts employee well-being, productivity, communication, and guest comfort. Selecting equipment with noise levels below 70 decibels is advisable to avoid such issues.

22. Heat Emission

Heat emission affects staff comfort and energy consumption. Commercial kitchens are high-temperature environments where cooking equipment like ovens, ranges, grills, and fryers generate high heat levels. These lead to discomfort and potential dangers in poorly ventilated spaces. Appliances with advanced insulation and heat dissipation systems help remove such issues and improve energy efficiency. Water-cooled ice machines, heat exchangers, heat-resistant materials, and ventless cooking equipment also minimize heat radiation. Remember to leave sufficient clearance around the heat-generating appliances during installation for proper airflow.

23. Environmental Impact

Pay attention to the environmental impact factor, which reflects your commitment to sustainability and responsible business practices when buying commercial kitchen equipment. Energy-efficient technologies, such as induction cooktops, LED lighting, and appliances crafted from recyclable or eco-friendly materials, minimize environmental footprint. Water-consumption features, like low-water faucets and dishwashers that use less water per cycle, also align with sustainability goals. Opting for greener products and practices resonates positively with eco-conscious consumers and promotes a more sustainable future for the industry.

24. Aesthetics

First impressions always matter, so aesthetics significantly enhances your business’s professional appearance. However, aesthetics is not merely how a specific piece of equipment looks but how it complements the overall ambiance. As different culinary concepts demand unique atmospheres, matching the equipment with the chosen style elicits an aesthetically pleasing environment, sharpening the brand image and customer perception. Here are some well-known theme-material matches listed below:

- Modern Kitchens: Brushed stainless steel is popular for its sleek, modern look. Glass and polished surfaces also boost this contemporary feel.

- Rustic Kitchens: Natural materials such as wood and stone evoke a cozy and rustic feel. Cast iron or distressed metals complement this style.

- Classic Kitchens: High-quality materials like polished wood, marble, and brass convey a sense of sophistication. Glossy or polished finishes create an elegant and refined look, supporting a luxury ambiance.

25. Automation

Automation is a transformative factor when buying commercial kitchen equipment. Automated features streamline processes, reducing labor and allowing kitchen staff to focus on more creative and complex culinary tasks. For instance, fully automated coffee makers grind beans, brew espresso, and even froth milk at the touch of a button, sparing baristas more time for customer interactions. So, always look for time-saving features in your appliance selections that are listed as examples below:

- Auto Basket Lift in Fryers: This feature automatically raises and lowers the frying basket in deep fryers, ensuring precise cooking times and reducing the need for constant monitoring.

- Auto-Refill in Dishwashers: Dishwashers furnished with auto-refill mechanisms eliminate the need for manual refilling by providing a continuous water supply.

- Automatic Cleaning Cycles in Ovens: Certain ovens have automatic cleaning cycles that use high temperatures to remove food residue.

- Self-Cleaning Function in Coffee Machines: The self-cleaning mechanism in high-end coffee makers flushes the internal components with hot water or steam to clean the machine between brewing sessions.

- Automatic Clean Cycle in Ice Machines: Ice machines with this function use water and cleaning solutions to sanitize the parts involved in the ice-making process.

- Programmability in Food Processors: Programmable settings let chefs automate repetitive tasks such as mixing, slicing, dicing, or kneading, saving time and assuring consistency in food preparation.

- Conveyor Belt System in Pizza Ovens: Conveyor pizza ovens automatically move pizzas through the oven chamber, perfect for even baking faster service in high-volume pizzerias.

26. Connectivity

Connectivity marks a technological leap that enables integration with kitchen systems. Modern equipment with connectivity features communicates with other devices, like POS, KDS, or inventory management platforms. With the introduction of IoT technology, operators can control and manage equipment remotely through a centralized system to:

- Access real-time data on equipment performance, status, and usage patterns.

- Identify potential issues, usage trends, and operational inefficiencies.

- Adjust operational parameters without a physical presence to address changing kitchen demands promptly.

- Collect and analyze data for predictive maintenance.

- Troubleshoot malfunctions without on-site visits.

- Send alerts and notifications to maintenance teams or chefs when the equipment deviates from the norm.

27. Customization

Customization is a pivotal factor when buying commercial kitchen equipment. It ensures that the appliances you buy fit your specific kitchen needs in layout, menu offerings, or other operational preferences. Many manufacturers offer customization options, such as bespoke sizes and finishes. For example, you can specify the top and base configurations of restaurant ranges separately. Adjustable shelving in storage units, refrigerators, walk-ins, and rack ovens or customizable blade attachments and speed controls in food processors optimize performance and flexibility.

28. Scalability

Scalability refers to a machine’s capacity to accommodate the growing needs of a business without immediate replacements or significant adjustments. Remember that scalable equipment seamlessly adapts to increases in production volumes or changes in menu offerings. Select versatile and modular appliances. For instance, an oven with additional rack space or capacity options is ready to handle a higher throughput as the kitchen’s demands rise. Scalable equipment provides a cost-effective and future-proof solution for evolving kitchen requirements.

6 Challenges in Commercial Kitchens

The relentless hustle and bustle in food service settings pose several challenges that influence the factors when buying commercial kitchen equipment. Satisfying voracious appetites and quenching the thirst of people with diverse taste preferences while maintaining staff content is a demanding task. Plus, technology and its incorporation in kitchen machinery is moving at a head-spinning rate. Staying tuned to the ever-changing needs requires awareness of the 6 challenges in commercial kitchens:

- Balancing High-Tech And Practicality

- Maintenance

- Training and Skill Gaps

- Ergonomics and Staff Well-being

- Cost Versus Value

- Adapting to Changing Culinary Trends

1. Balancing High-Tech and Practicality

As technology evolves and transforms lifestyles, advanced technology is increasingly becoming a key factor when buying commercial kitchen equipment. Yet, over-reliance on advanced equipment can lead to practical issues. Overly complex appliances lead to extended training periods. It takes staff longer to adapt quickly. Also, technical issues with intricate technologies increase downtime. So, you should follow the list below to find a harmonious balance where technological solutions add value without impairing the practical aspects of kitchen operations:

- Evaluate your kitchen’s real needs and challenges to invest in technology that directly handles these: don’t buy a machine just because it has the latest technology.

- Apply comprehensive training to introduce the high-tech equipment to your staff.

- Prefer appliances that have a user-friendly operation to lessen the learning curve.

- Partner with suppliers that guarantee quick response times for troubleshooting and addressing your technical issues.

- Conduct pilot programs and testing phases before procuring high-tech equipment.

- Schedule proactive maintenance to prevent unexpected breakdowns.

- Have backup options or manual alternatives in case of technology failure.

2. Maintenance

Maintenance stands as a persistent challenge in commercial kitchens. The high volume and intensity of kitchen activities potentially cause neglect of regular maintenance. Poorly maintained equipment is prone to breakdowns. Lack of routine upkeep also means compromising food safety standards. Over time, not recognizing the common oversight of maintenance and its impact leads to increased repair costs, decreased equipment lifespan, and health and hygiene concerns. Addressing this challenge requires a proactive approach. Purchase appliances with features that facilitate servicing. Such features include:

- Manufacturer’s continuous support for routine upkeep

- Accessibility of machine components for cleaning and maintenance

- Availability of replacement parts

- Simple disassembly for servicing

- Functions like self-cleaning or quick care

- Self-diagnostics that alert users in case of irregularities

- Smart systems that allow remote maintenance

Alternatively, some buyers favor brands or models known for durable construction and reliable performance, not to worry about all these. They hope to reduce the frequency of breakdowns and maintenance headaches.

3. Training and Skill Gaps

Staff training is already a dynamic factor when buying commercial kitchen equipment. Yet, the initial training doesn’t always suffice to catch up with the rapid evolution of culinary technologies. Staff needs systematic training to update themselves and close the skill gaps. Remember that proficient and knowledgeable employees enhance operational efficiency and lower the risk of equipment misuse and damage. Proper staff training has the power to transform your business. The strategies below help you address the training challenge:

- Develop well-structured comprehensive training programs that cover the new equipment’s functionalities, safety protocols, and maintenance procedures.

- Conduct hands-on workshops and invite active participation to give your personnel a more practical understanding.

- Provide access to online resources, manuals, and video tutorials to gear staff towards ongoing learning.

- Implement regular refresher courses to update staff and close skill gaps.

- Encourage peer-to-peer learning.

4. Ergonomics and Staff Well-Being

Ergonomics for commercial kitchen designs means creating environments and equipment that improve efficiency, safety, and comfort for individuals working within the space. It is necessary to optimize staff well-being by considering the physical demands of their tasks, minimizing repetitive motions, reducing strain on the body, and promoting overall health and safety. Developing and implementing ergonomic design is a challenging task that involves in-depth workspace analysis and planning. You can follow 5 practical tips listed below:

- Select equipment with ergonomic designs that reduce strain on the user, such as adjustable heights, easy reach, and user-friendly controls.

- Configure kitchen workstations based on ergonomic principles, like the work triangle concept, to ensure tools and ingredients are easily accessible, and work surfaces are at comfortable heights.

- Place anti-fatigue mats in areas where employees stand for extended periods to decrease impact on joints.

- Encourage regular breaks and rotation of tasks to prevent repetitive strain injuries and let staff recharge during demanding shifts.

- Monitor the plan you implement and collect feedback to make adjustments.

5. Cost Versus Value

Cost is undeniably one of the top-rated factors when buying commercial kitchen equipment. This is understandable, considering loads of money spent on equipment procurement. Yet, does it always correlate with the overall value for money? Foodservice operators need to ask themselves this question and find ways to address the dilemma between choosing cost-effective and value-adding equipment. Consider the ways listed below to balance the immediate costs and long-term value:

- Consider energy efficiency, maintenance requirements, and expected lifespan to reduce the total cost of ownership.

- Evaluate the potential return on investment by weighing the equipment’s benefits and gains against its upfront costs.

- Compare features and functionality of different equipment options and prefer durable, versatile, and flexible ones to get long-term value.

- Seek insights from kitchen consultants, seasoned chefs, and user reviews to gain insights into the equipment’s real-world performance and satisfaction levels.

- Allocate for regular maintenance and repairs budget to extend the equipment’s lifespan and avoid more costly breakdowns.

- Assess the manufacturer’s reputation for quality, customer support, and reliability since these often reflect the overall value offered by its products.

6. Adapting to Changing Culinary Trends

The food and beverage industry has a dynamic future, with changing culinary trends based on customer preferences and advanced technologies. Adapting to these poses a constant challenge for chefs and kitchen operators. As tastes and food trends change rapidly, flexibility in menu planning, ingredient sourcing, and incorporation of innovative cooking techniques becomes imperative to remain competitive. Below are listed 6 easy-to-apply strategies for following emerging trends and quickly adapting them.

- Read blog posts and other publications about top culinary trends, customer preferences, and industry innovations.

- Use smart systems like KDS to streamline menu planning and flexibility.

- Foster collaborations with other chefs and professionals to exchange insights, share ideas, and stay connected with the latest developments.

- Encourage your chefs to experiment with new ingredients, cooking techniques, and flavor combinations.

- Design an adaptable kitchen layout to reconfigure the equipment and workstations easily when necessary.

- Establish customer feedback channels, including reviews and social media interactions, to tailor your menu accordingly.

Conclusion

Selecting the right commercial kitchen equipment is a multifaceted decision involving careful consideration of 28 critical factors. From cost and kitchen layout to energy efficiency, safety, and technological features, each element plays a vital role in ensuring operational efficiency, culinary excellence, and customer satisfaction.

Navigating the six key challenges in commercial kitchens – balancing high-tech features with practicality to adapting to changing culinary trends – is essential for modern foodservice operations. By thoughtfully addressing these factors and challenges, restaurateurs and chefs can create a well-equipped, versatile, and efficient kitchen environment that meets the current needs and is adaptable to future demands. This holistic approach to selecting commercial kitchen equipment is fundamental to building a successful, sustainable, profitable food service business.